Introduction

The manufacturing sector is undergoing a profound transformation in today's digital age. Integrating digital technologies and Industry 4.0 initiatives has led to the rise of smart factories, the Internet of Things (IoT), artificial intelligence (AI), and automation. While these advancements bring numerous benefits for manufacturers, they expose them to cyber threats. As a result, the future of cybersecurity in manufacturing is poised for significant improvements.

With the increasing adoption of digital technologies, the attack surface for cyber threats expands exponentially. According to a 2019 report from Deloitte, 48% of manufacturers identified operational risks, which include cybersecurity, as the greatest danger to smart factory initiatives.

Manufacturers face the challenge of safeguarding critical operations and intellectual property from malicious actors constantly evolving their tactics. As a result, innovative approaches to cybersecurity are essential to protect sensitive information and ensure the smooth functioning of manufacturing processes.

Key Factors That Will Drive the Evolution of Cybersecurity in Manufacturing

Several trends and predictions are shaping the future of cybersecurity in the manufacturing sector.

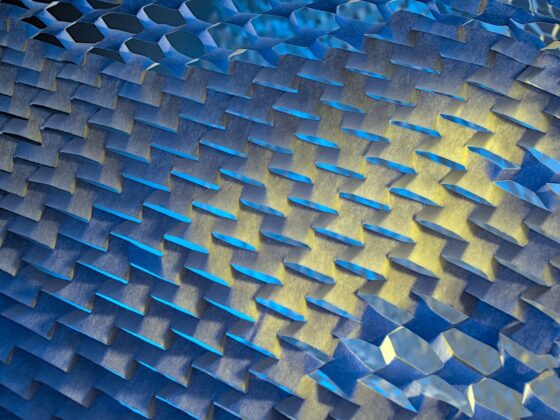

Increased Connectivity and IoT Adoption

The proliferation of IoT devices in manufacturing environments will continue to grow, enabling seamless communication between machines, sensors, and systems. While this connectivity enhances productivity and efficiency, it also expands the attack surface, making manufacturing facilities more susceptible to cyber threats. Securing these IoT devices and managing their vulnerabilities will be a top priority for manufacturers.

Convergence of IT and OT

As manufacturing operations merge with information technology (IT) systems, the intersection of IT and operational technology (OT) networks will intensify. While this integration brings numerous benefits, it blurs the lines between traditional IT and OT security. Manufacturers must develop holistic cybersecurity strategies encompassing both domains to protect critical production processes and sensitive data.

Artificial Intelligence (AI) and Machine Learning

Cybersecurity solutions powered by artificial intelligence (AI) and machine learning (ML) will play a significant role in the future of manufacturing security. These technologies can analyze vast amounts of data in real-time, detect anomalies, and respond to threats faster than human capabilities. AI-driven cybersecurity tools will become essential for manufacturers to proactively defend against evolving cyber threats.

Supply Chain Security

The manufacturing sector relies heavily on complex global supply chains, making it susceptible to cyber attacks on suppliers and partners. A breach in the supply chain can have far-reaching consequences, disrupting operations and compromising sensitive data. Manufacturers will place greater emphasis on securing their supply chains as cybercriminals increasingly target third-party vendors and partners. Manufacturers can minimize the risk of supply chain disruptions and data breaches by ensuring the security of suppliers' systems and processes.

Cloud Security

As manufacturing companies embrace cloud services for data storage, analytics, and collaboration, cloud security will gain prominence. Manufacturers will seek robust encryption, authentication mechanisms, and regular audits to safeguard sensitive data in cloud environments.

Zero Trust Architecture

The adoption of Zero Trust security principles will become increasingly prevalent in manufacturing environments. Zero Trust assumes that no device or user is inherently trusted, and each interaction must be verified before access is granted. Manufacturers will implement stricter access controls and micro-segmentation to reduce the impact of potential breaches and unauthorized access.

Incident Response and Recovery

In anticipation of cyberattacks, manufacturers will focus on improving incident response and recovery capabilities. Rapid detection, containment, and remediation of cyber incidents will be vital in minimizing the impact on production and business operations.

Regulation and Compliance

The manufacturing sector will face increasingly stringent data protection and cybersecurity regulations. Compliance with industry-specific standards and government mandates will be necessary to avoid financial penalties and reputational damage.

Cybersecurity Talent Shortage

The demand for skilled cybersecurity professionals will outpace supply, leading to a talent shortage in the manufacturing industry. Manufacturers will address this challenge by investing in workforce development, collaborating with educational institutions, and leveraging managed security services.

Conclusion

The increasing digitization of processes, IoT adoption, AI-driven solutions, and the convergence of IT and OT will shape the future of cybersecurity in manufacturing. As cyber threats become more sophisticated, manufacturers must proactively implement comprehensive cybersecurity strategies to protect their operations, data, and reputation. Manufacturers can thrive in the digital era by staying ahead of emerging trends and adopting innovative security measures while safeguarding their valuable assets.

Empowering Organizations to Maximize Their Security Potential.

Lares is a security consulting firm that helps companies secure electronic, physical, intellectual, and financial assets through a unique blend of assessment, testing, and coaching since 2008.

15+ Years

In business

600+

Customers worldwide

4,500+

Engagements

Darryl has over 20 years experience in the IT security sector, having been responsible for developing, managing and assessing information security programs for all levels of enterprise and government level organizations.

He has spoken at multiple conferences such as Security BSides St.John’s and GoSec. He also sits on the Board of Directors for AtlSecCon and is the former lead organizer for Security BSides Cape Breton.